Introduction

3D printing, CNC machining, and vacuum casting have all emerged as viable production options, but each has distinct material capabilities and suitability for different volume needs.

For companies developing prototypes or producing goods, the choice of manufacturing technology is crucial. Selecting the right method can mean the difference between an on-time project and missed deadlines, or a costs that meets versus exceeds budgets. As manufacturing requirements become more advanced, it is imperative that professionals understand the strengths and limitations of these technologies.

This guide provides an in-depth comparison of 3D printing, CNC, and vacuum casting from an industrial perspective. We’ll discuss factors like production volumes, material options, workflows, tolerances, surface finishes, and of course costs. By reading this article, manufacturing and product development professionals will be equipped to evaluate which process best fulfills their specific technical and budgetary requirements.

3D Printing: the Versatility of Additive Manufacturing

3D Printing Process: How it Works

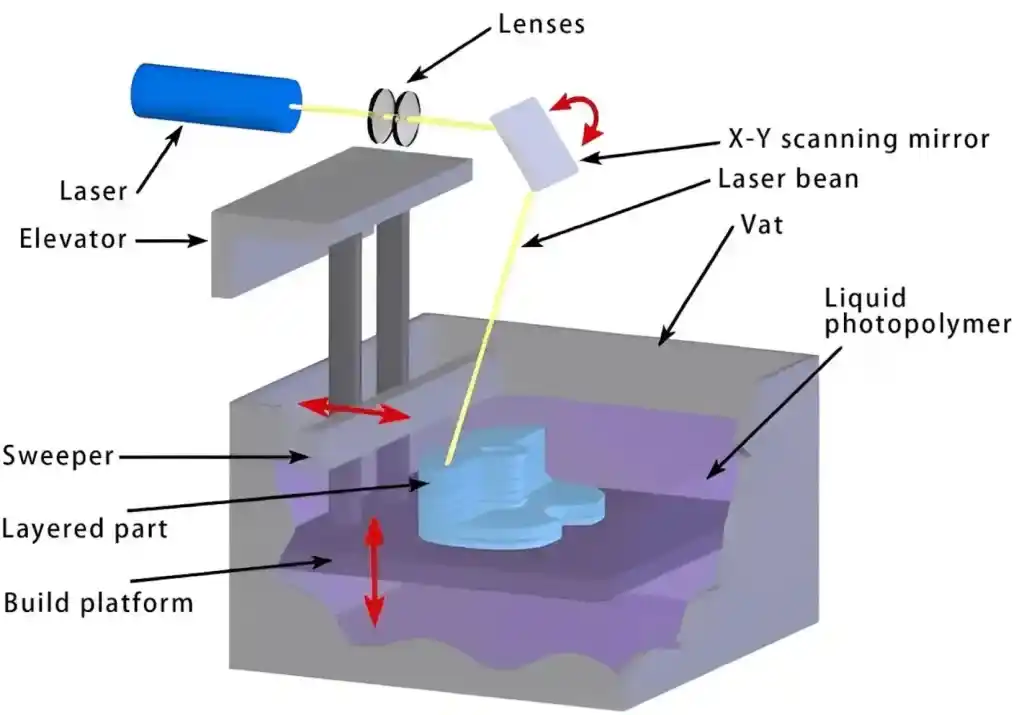

3D printing (also known as additive manufacturing or AM) involves building three-dimensional objects from a digital file through successive layers of material.

The general 3D printing process works by first designing a virtual 3D model using computer-aided design (CAD) software. This 3D model is then sliced into thin cross-sectional layers and sent to the 3D printer. During printing, materials such as plastic, metal, ceramic, or other materials are selectively deposited one layer at a time until the final object is completed.

Main 3D Printing Technologies: SLA, SLS and SLM

The main technologies used include Stereolithography (SLA), Selective Laser Sintering (SLS), and Selective Laser Melting (SLM). SLA provide high resolution while SLS and SLM can process industrial-grade materials suitable for end-use manufacturing applications.

If you want to learn more, this article provides a detailed comparison of SLA, SLS and SLM.

3D Printing Materials

Common materials used in 3D printing include plastics like ABS and PLA, metals including stainless steel and titanium. Powder-based systems like SLS and SLM can 3D print using nylon, plastic and polymer powders as well as metal and ceramic powders.

Typical Applications of 3D Printing

Areas where 3D printing truly excels include low-volume production of customized components, rapid prototyping to validate part functionality, creating intricate internal structures or geometries otherwise not possible, and producing specific parts for applications like medical implants or bespoke automotive components. Overall, 3D printing technology enables new frontiers in customized, on-demand manufacturing.