MEDICAL

Numerous precision parts, special material parts, early prototype production and later small-batch production are involved in medical devices. CNC machining is a frequently-used manufacturing process, and it can meet the high requirement on the tolerance of precision manufacturing. Rapid prototyping, an essential link in the development stage, is used to verify the rationality of medical equipment design, for the sake of saving the development time and cost. Small-batch production can enter the market quickly and reduce the risks relating to the investment cost.

medical device & hardware applications

Medical testing equipment

Ventilators parts

Handheld devices

Implantable prototypes

Surgical instruments

Prosthetic components

Custom fixturing

Wearables

Medical Manufacturing Capabilities

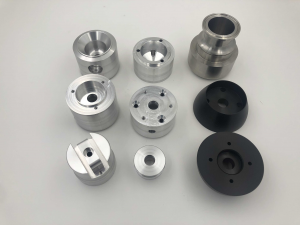

CNC Machining Service

We possess precision CNC machine tool shop capable of working out parts with the most severe tolerance and processing metal and plastic prototypes as well as production parts as soon as one day.

Injection Molding Service

Our small-batch injection molding features with fast delivery time, we utilize rapid tooling to expedite the manufacturing cycle of products, enable products to enter the market faster and reduce investment risk

3D Printing Service

Rapid prototyping of 3D printing allows you to complete complex parts easily and quickly, and we will provide you with high-quality additive manufacturing services from precision prototypes to small-batch production parts.